No doubt, it is one of the frequently asked questions. I’m sure at some point you have also wondered what is underneath that aesthetically pleasing top sheet.

Probably thinking, it’s nothing more than a few wooden planks? Then how does each piece performs differently?

That’s exactly what I am here to answer. Each manufacturer follows a slightly different method to manufacture snowboards, however, the basic structure stays the same for all.

In this article, we will explain what are snowboards made of and discuss the basic sandwich construction overlay of a snowboard, its materials, and its functions.

What Are Snowboards Made Of?

To get an answer, first you need to understand the anatomy of a snowboard, which is exactly the same in all snowboards doesn’t matter which company you buy from.

Your deck is made of several different parts, each part possesses different qualities, and all these together make an exquisite snowboard. Let’s break down the basic parts that make up a deck!

- Topsheet

- Core

- Fiberglass

- Epoxy

- Sidewall

- Edges

- Base

- Mounting System

There Are Few Common Materials in a Snowboard Construction

Now, let’s throw light on each component individually.

Core Construction:

So, what do I call the snowboard’s core? The building block. The snowboard core makes the very center of the snowboard, hence the most important component. The remaining components are constructed around it, so it should act right. Shouldn’t it?

This central structure determines a lot of characteristics of your deck. I mean, this is a supplier where the main strength lies and everything gain supports from it.

Most of the decks, even today are made out of traditional wood as it poses the perfect choice for a deck, while some cheap options are manufactured using a foam core. Why wood? Because it has less resonance than plastic or foam.

The most common wood options are birch, bamboo, beech, aspen, poplar, obeche, and paulownia. Strips cut out of any one of these woods are vertically and horizontally laminated or arranged in different other patterns and then shaped to create various types of flexes.

Besides wood, snowboard brands also tend to use other core materials like aluminum honeycomb, carbon fiber, kevlar, polyurethane, and fiberglass. Carbon is known for making a lightweight, lively and strong deck with very good under compression but very elite. I mean, very expensive, only elite can afford it.

Kevlar is a strong synthetic fiber known for making a strong and reasonably light deck ideal for terrific performance under tension in all types of snow conditions.

On the other hand, aluminum honeycomb swanks reduced damping capabilities but stand expensive. While a foam deck isn’t that durable, thus used in low-stress areas. It is a bit soft so lacks performance.

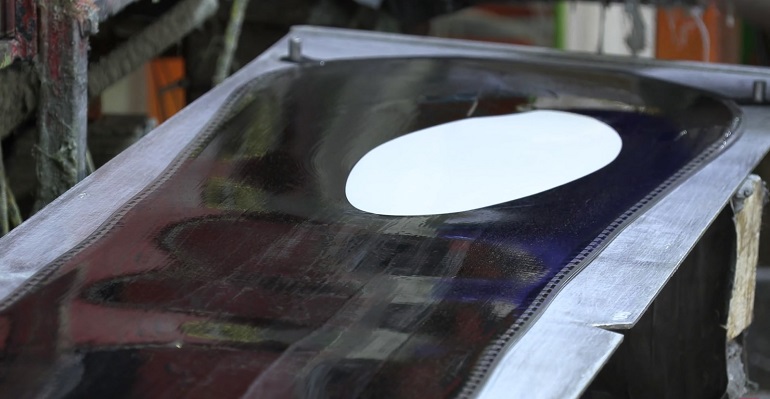

Topsheet with Printed Graphic:

A top sheet or top layer of the snowboard is not only the shield of the board but also a canvas for manufacturers. Top sheets are constructed using nylon, fiberglass, composites, wood, or plastic.

Typically there are two types of top sheets: glossy or matte. The matter top sheets have screened-on graphics, while glossy top sheets come with sublimated graphics. Cannot wrap your head around it? Allow me to further simplify it for you.

There are mainly two ways to put attractive graphics on a deck:

Sublimation:

In this process, graphics are fused into the material that makes the top sheet using special different inks, plastics, and heat. This way, graphics become a part of the top sheet, so even if you scratch it, graphics will still be there.

Encapsulation:

It involves placing a graphics sheet under the top sheet. The paper, cloth, or any other suitable material onto which graphics were printed is put under a clear top sheet or lacquer on the top sheet. The material of the graphic sheet and the inks are chosen carefully, as the wrong pick can damage the top sheet and the fiberglass underneath.

Fiberglass

The standard fiber material utilized for the construction of a sheet above the core is fiberglass. This industry-standard composite fiberglass reinforced plastic material provides stiffness and strength to the snowboard.

The function of this is to protect the core while also keeping the board from losing its form and shape. When I say the top sheet is the armor, I mean it, as it keeps the board from getting deformed or reshaped.

Fiberglass layers are structured around the core using one of the below mentioned two ways:

Bi-axial Wrap

In this method, the fiberglass strands are weaved at 90 degrees to each other. This construction provides a more forgiving and softer flex. Such snowboards are suitable for riders who are living for tricks and jumps.

Tri-Axial Wrap

When you get bored of a soft flex board, that’s when you know you need to upgrade from bi-axial to tri-axial. In this method, the fiberglass strands are weaved together at +45 degrees, zero degrees, and -45 degrees.

This construction gives a lightweight dependable board with enhanced stiffness and better response. The stiffer torsional flex permits the deck to hold a higher level of force, which results in a more stable experience for a rider.

Steel Inserts:

Metal inserts are stainless steel inserts that are used to mount your bindings on the deck. These built-in inserts are used by the rider to put force into the snowboard and ride it as they desire.

The mounting systems of snowboards are distinguished by the hole pattern they feature. Common hole patterns on snowboards include 3D, 4×4, 4×2, and Channel. These holes feature stainless steel inserts to mount bindings, and the reason why they are made out of stainless steel is to prevent them from rusting.

Plastic Base:

The snowboard base is one of the most important components of a snowboard. And you need to look out for it while shopping. Why? Because the base should act like a base, otherwise, the building will come crashing down.

It is the bottom-most layer of a snowboard that is in direct contact with the snow underneath. Now, do you see why it makes an important part of a deck?

The industry standard mostly uses Ultra-High-Molecular-Weight polyethylene plastic (P-tex). It is an extremely durable thermoplastic material used for base support in boards.

What makes it special is its numerous qualities. It is abrasion-resistant plastic that is durable, easily repairable, and has low friction properties. One can easily wax it also for a slippery surface.

I suggest you choose a winter sports company that puts much effort into the making of the base. The process used for the making should be a proven process as it will translate to a long-lasting deck and a carefree smooth ride.

Metal Edges:

Have you noticed those smooth metal sides that run along the length of a snowboard? These are called edges. While buying, think: No metal, zero edges. Yes metal: ample edge.

Metal edges are made of steel or stainless steel, and are secured to the board using built-in T-shaped inserts. You will notice two types of edges: full wrap and partial wrap.

Full-wrap or complete metal edges go all the way around the board ending at a single point. This type can be hard to repair if heavily damaged.

On the flip side, partial steel edges go all along the perimeter of the board, which means, just along the sides of the board. You need to notice that in this method less metal is used which makes a board lightweight than the one with full wrap edges.

Now let’s talk about how the edges influence a deck’s performance. Steel edges can take a beating for the life of a board, and demands little maintenance like cleaning and sharpening.

While on the other hand, stainless steel metal edges provide the same level of performance with the advantage of rust resistance.

Resin System:

Epoxy or resin is what keeps all the components of a snowboard bonded together. The resins used in a board are made strong, flexible, and tolerant to low temperatures. The epoxies are engineered using specific directions to provide special adhesion for the fiberglass layers and other parts.

Not to mention, such resins are petroleum based mostly which can harm the environment. If you are an ethical consumer, you can buy decks from those companies that advocate carbon footprint reduction.

Rubber Foil:

Also named VDS, a rubber foil is used as a vibration dampener and also acts as a bonding agent. This thing skillfully regulates the vibrations while also sticking together the steel and fiberglass. You know, steel is hard to connect to the glass, so VDS is applied on top of the deck edge for a stronger bond.

What Material Is Best for Snowboarding?

Wood core snowboards! Yikes! Wood makes a perfectly durable yet functional, high-performance snowboard that no other material can. Alright, kevlar and aluminum don’t give me those looks, but you two are out of our leagues.

In wood, poplar delivers the perfect qualities for high-quality snowboard construction. It helps retain the shape, bolster vibration damping, and show less resonance in comparison to other materials like plastic or foam.

Final Thoughts

No one likes to witness their money going to the trash can after just multiple rides in hard snow. Knowing what your deck is made of is important for your wallet’s safety as well as your own safety.

Mark my words, all snowboards are made by hand and the higher-quality snowboards can last for years and years, only if you know how to use and store a snowboard after a good use. Snowboards come in different materials for various riding styles like freestyle boards different than all-mountain boards.

Choosing a snowboard is a difficult task, I agree. Especially when the market is saturated with millions of options. Back in the 60s and early 70s, snowboards were mere pieces of wood with nothing out of the box, but each product of today’s world possesses a unique property.

The world has advanced much in technology and materials. Snowboards being offered today swank different features and different base materials meant for different purposes. You need to find the right one for you by digging deep into the details.

0 Comments